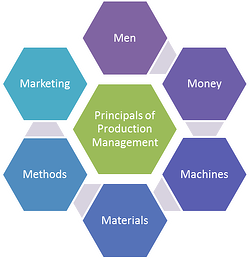

Production management involves the planning, organisation, direction and execution of production activities. The ultimate goal of any production management solution is to convert a collection of raw materials into a finished product. Some people refer to production management as the bringing together of the 6 'Ms':

- Men

- Money

- Machines

- Materials

- Methods

- Markets

These constituents come together to provide consumers and businesses with products that they need or want.

The production management principles are often referred to as operation management principles, and they are designed to facilitate the production of goods that are of the required quality and quantity.

An efficient production management solution will also deliver products at the time they are required by the market at the lowest achievable cost. Any successful production management solution requires the optimum utilisation of production capacity in order to reduce costs to a minimum.

7 Primary Principles of Production Management

Shorter set-up times.

By their nature, all set-up processes result in waste; they tie up labour and equipment without adding value. Training, improved efficiency and giving workers accountability for their own set-ups allowed Toyota to slash their set-up times.

Small-scale production.

Cutting the cost and time spent on set-ups allows a company to produce goods in smaller batches and according to demand. This results in lower set-up, capital and energy costs.

Empowering employees.

Dividing a workforce into small teams and giving them accountability for housekeeping and various other tasks has been shown to improve efficiency. Teams are assigned leaders, and the workers within those teams are trained on maintenance issues - allowing them to deal with delays in the production process immediately.

Equipment Maintenance.

Workers on the line are best placed to deal with mechanical breakdowns and subsequent repairs. They can react to issues quickly and often without supervision, which allows the production process to restart far more quickly after a shut-down.

Pull Production.

In a bid to minimise inventory holding costs and production lead times, Toyota pioneered a system whereby the quantity of materials, labour and energy expended at every stage of the process was solely reliant on the demand for products from the next stage of production.

Often referred to as Just in Time (JIT), this principle was aimed at producing goods according solely to the demand for them at any given time, thus eliminating unnecessary costs.

Supplier Involvement.

Toyota demonstrated that treating component and raw material suppliers as integral components of their own production process led to a number of benefits. Suppliers were given training in Toyota processes, machinery, inventory systems and set-up procedures. As a result, their suppliers were able to react positively and swiftly when problems occurred.

What Are the Main Advantages of an Effective Production Management Solution?

There are several benefits to implementing the basic principles of production management; they include a good reputation within a specific market and the ability to develop new products and bring them to the market quickly.

Reducing costs at every stage of the production process provides the main benefit of cutting a company's overall costs. A manufacturer obviously does not want to incur costs when there are no orders, and an effective production management solution - such as the one pioneered by Toyota - should make that an achievable goal.

Because firms adopting the principles of production management can keep a tight lid on their costs, they can have a competitive edge in the market, and that can allow them to grow far more quickly than would otherwise be the case.

Companies like Toyota were able to take on the likes of Nissan and Ford in international markets because their innovative production management solution guaranteed quality for the consumer and lower costs for the business - and that's why the principles are now being implemented in manufacturing industries across the world.

.png?width=120&height=120&name=MicrosoftTeams-image%20(4).png)